Pipe supports

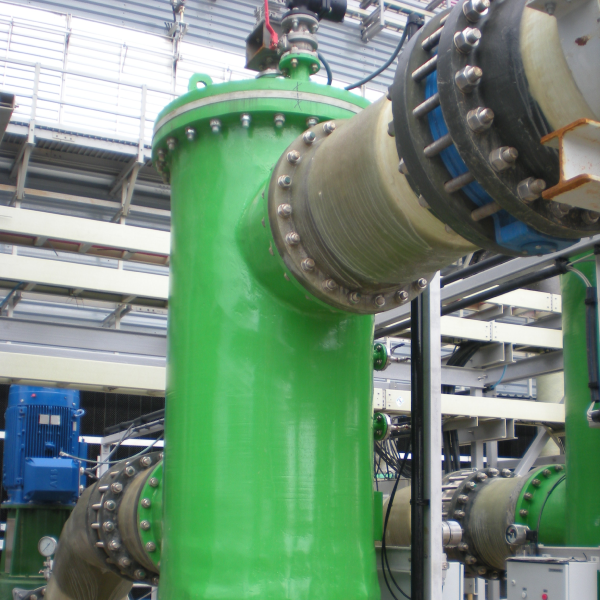

PIHASA’s main activity is the manufacture and supply of pipe supports and hangers for industrial pipes. Our products are particularly relevant when there are thermal movements due to high or low temperature operation conditions.

We have a very extensive technical catalogue for standard components that will cover most if not all your needs related to spring supports, rigid supports, sliding supports, hangers, struts, etc., for a very wide range of sizes, loads and temperatures.

In addition, our technical department and our material means are qualified to design and fabricate all sorts of special designs and catalogue variations, in order to adequate our products to our clients needs or to make components in strict accordance with third party standards.

Thanks to our broad human and material capacity and our strong financial background, we can prove competitiveness with a reputed ability to offer the shortest possible delivery times.

Variable spring supports

Spring supports allow vertical pipe displacement due to thermal expansion or contraction, and support the weight of the pipe system. In a variable spring support, load varies at a constant rate with the vertical travel. For that reason, they are used when the vertical movement is of a low or medium range (up to 50-75 mm).

There is a wide range of models, sizes and types in order to cover a very extensive range of loads, travels and installation configurations, being used as a hanger (above the pipe) or as a support (below the pipe).

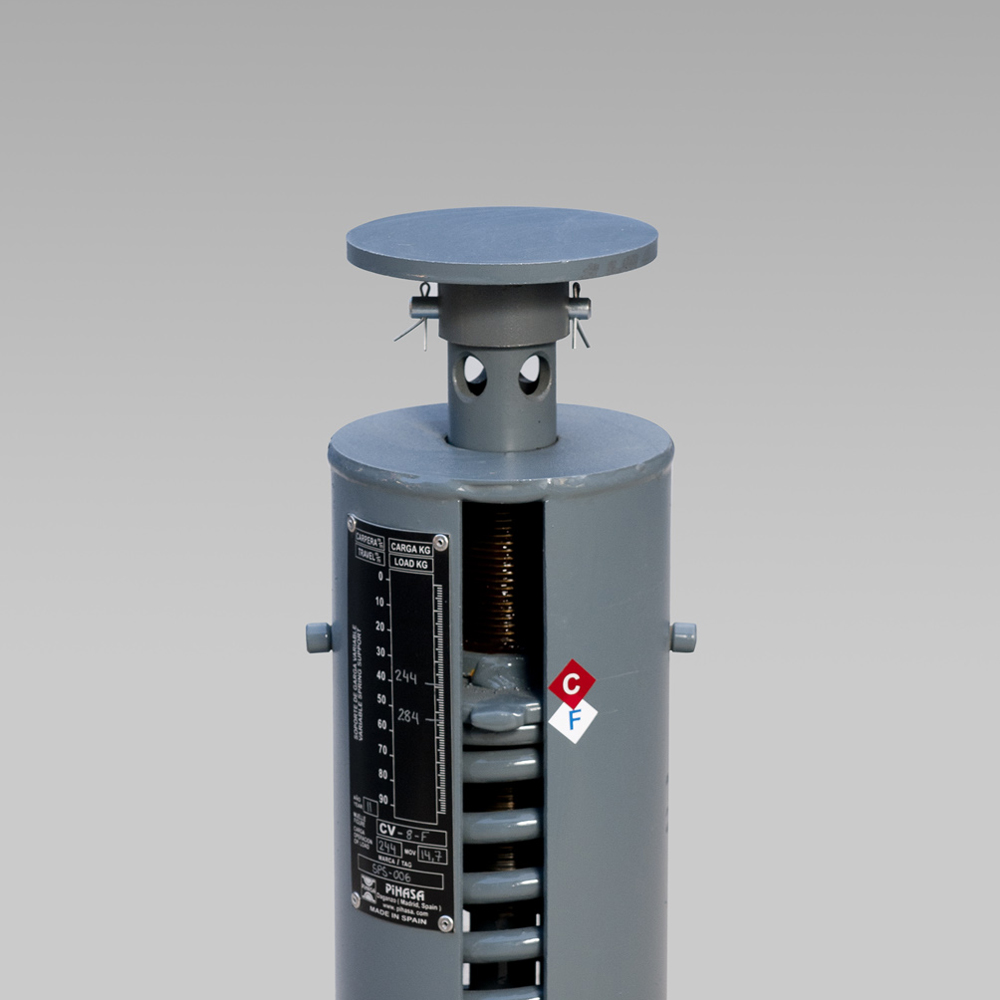

Constant spring supports

Constant spring supports allow vertical movements of the pipe due to thermal expansion or contraction and have a fixed load output throughout their travel range. They are used when vertical movement is high (from 50-75 mm upwards) and when stress at the pipe nozzles and equipment has to be very limited.

There is a wide range of models, sizes and types in order to cover a very extensive range of loads, travels and installation configurations, being used as a hanger (above the pipe) or as a support (below the pipe).

Hangers

We have a wide range of standard catalogue components (rods, eye nuts, clevises, turnbuckles, clamps, lugs, beam attachments, etc.) that combine to make hanger sets. Pipe hangers can withstand the load of the pipe and avoid friction loads associated with resting supports. Designed at an appropriate length that keeps angulation due to horizontal movements within an acceptable range, they are very versatile and there can be found many installation solutions.

In addition, these components serve as accessories for spring units in order to make a complete spring hanger.

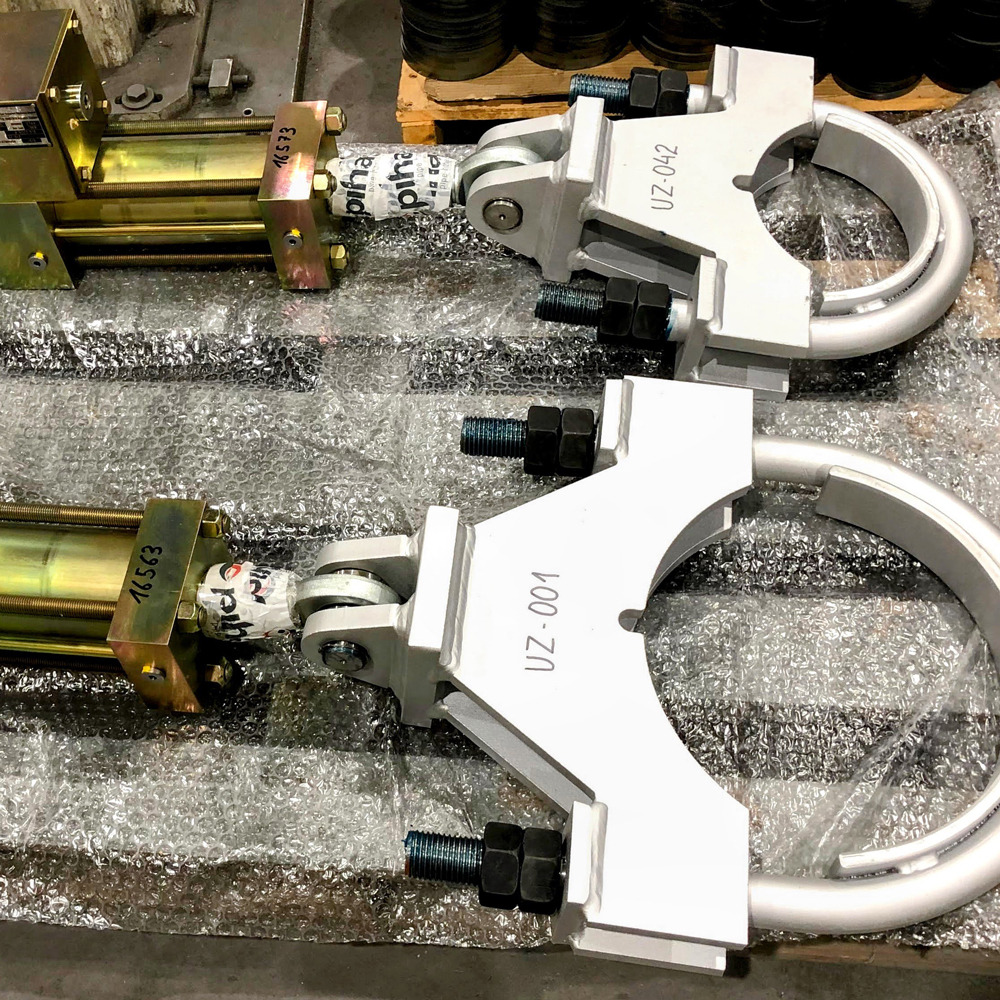

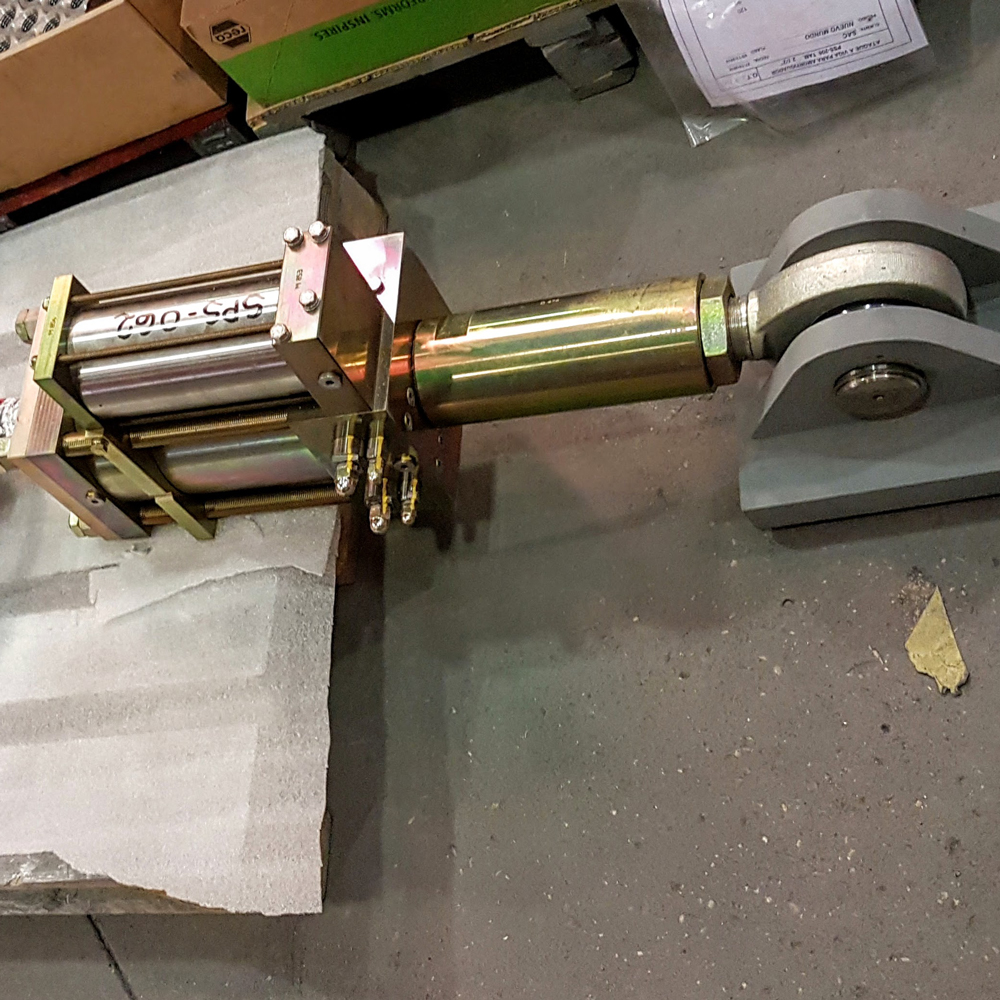

Struts

Struts are linear articulated supports characterized by their high rigidity that restrict the movement of pipe in their axis direction.

As with hydraulic shock arrestors, they can be installed in any position with relation to the pipe depending on the direction of the movement that they are designed to restrict. They connect to the adjacent structure by the use of special beam attachments (“rear bracket”), and they connect to the supported pipe with dynamic clamps (option 1) or with highly rigid plate clamps (option 3). They can also be used for supporting equipment or to connect with trunnions or welded shoes by the use of a rear bracket on the supporting end (option 2).

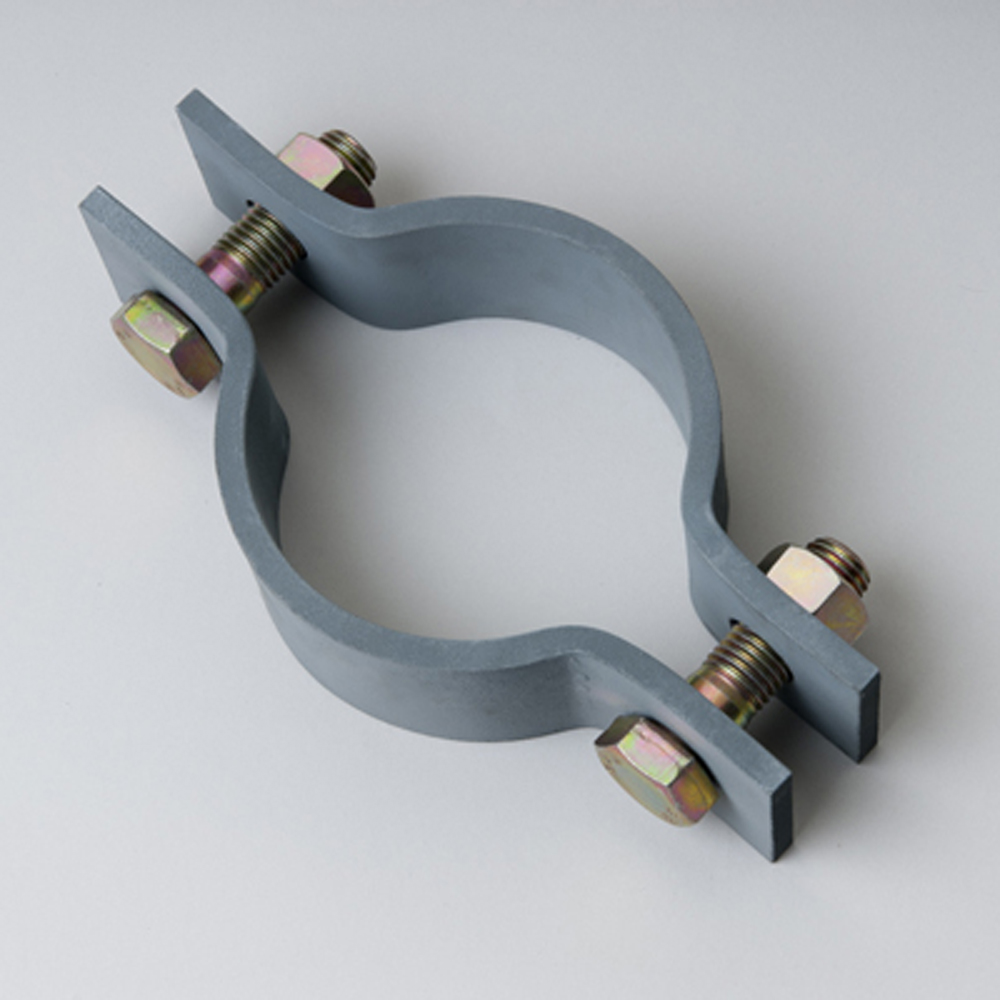

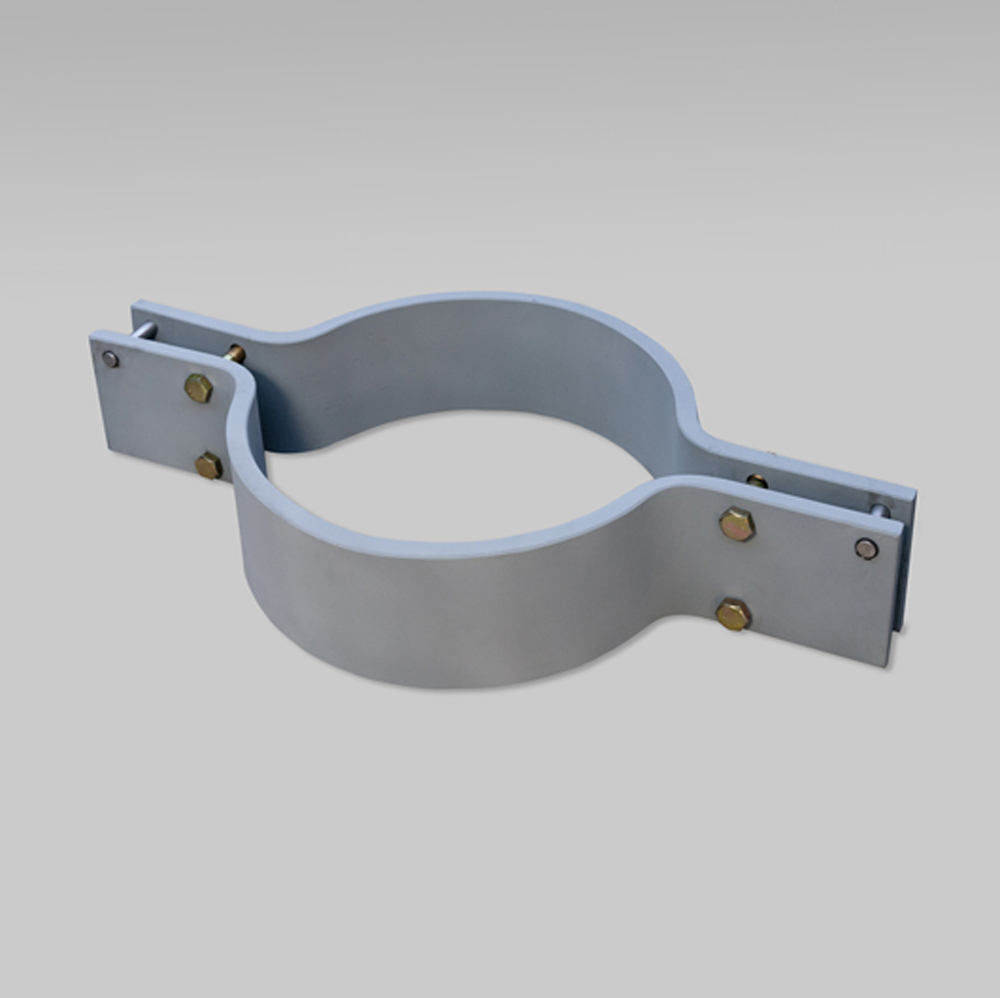

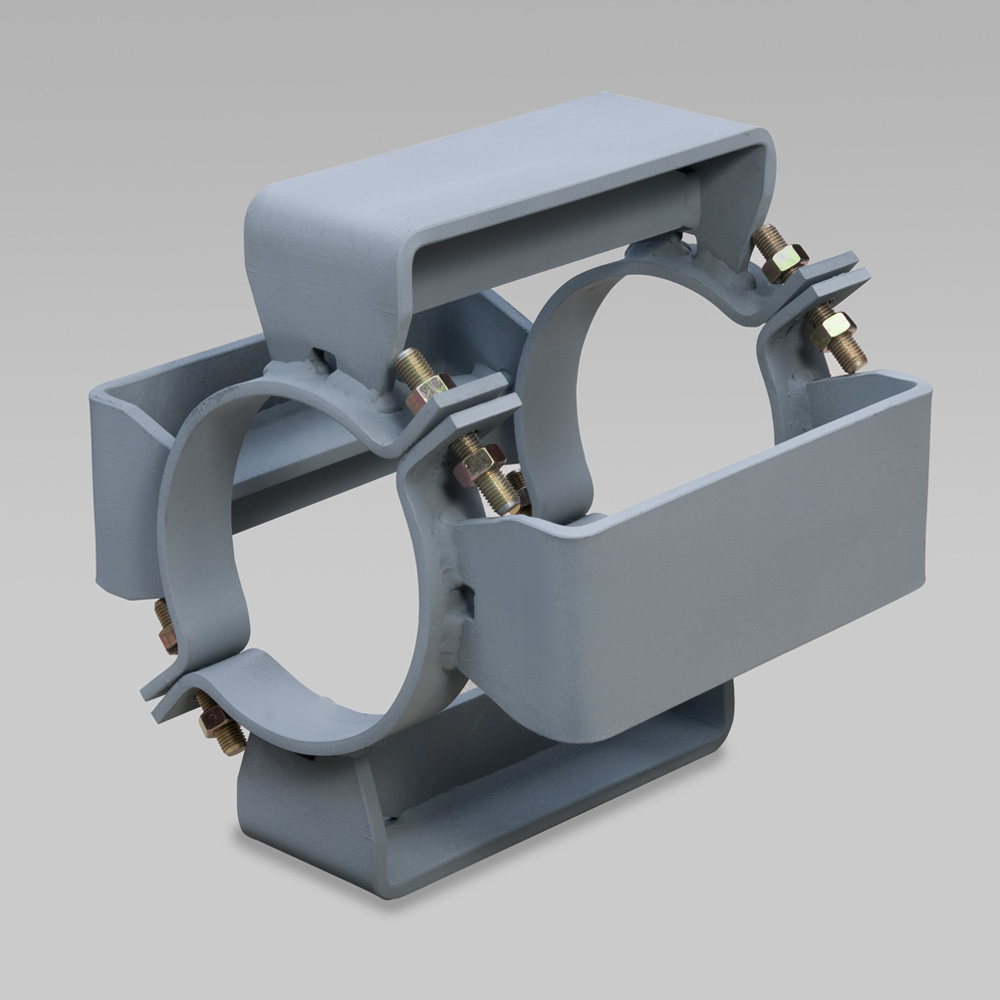

Shoes, u-bolts and components for guides and anchors

Resting supports are the most common pipe supports given their high degree of standardization and ease of installation, specially for pipes that rest on structures and pipe racks.

They can be used as a free sliding support, or as guides and anchor points.

At PIHASA we are very specialized and flexible at the manufacture of u-bolts, guide clamps and clamp shoes of all sizes, dimensions, qualities and types. We can adapt our basic designs to any given combination of pipe diameter, loads, temperatures, expected movements and function designed by our client’s engineering.

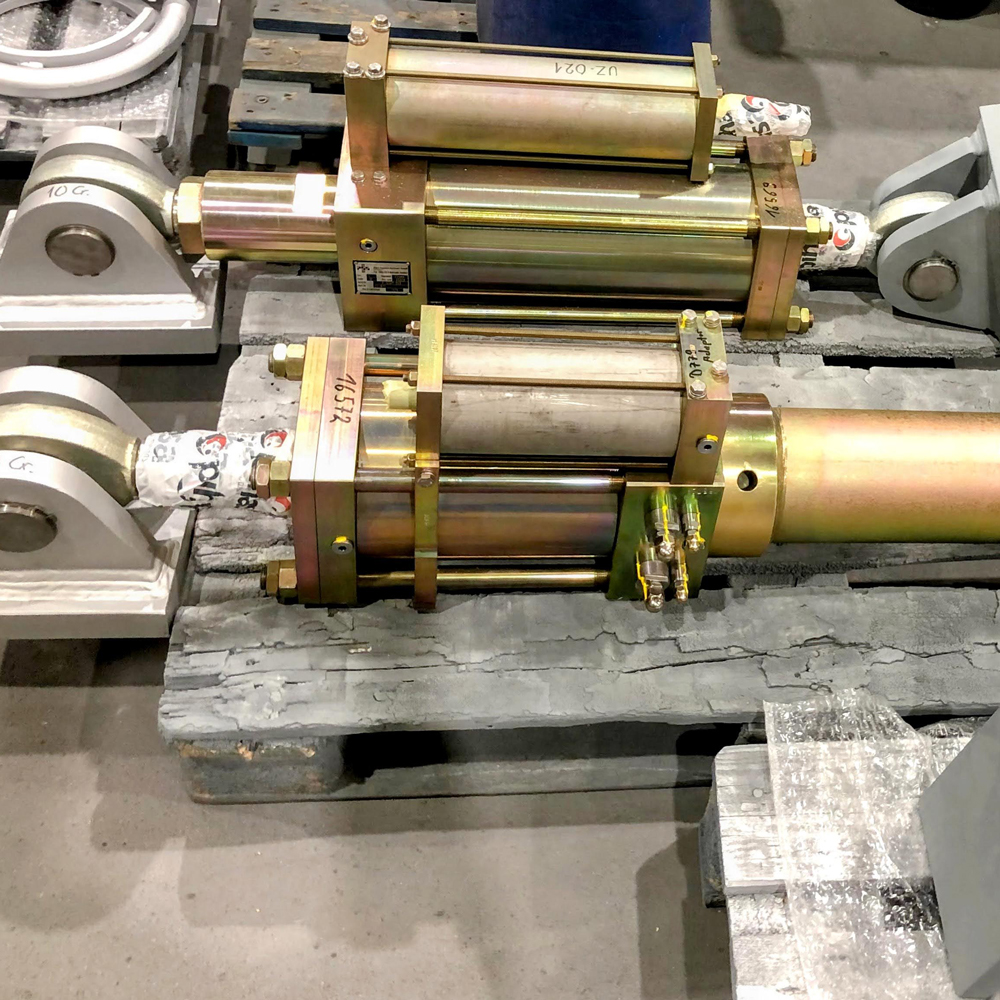

Hydraulic snubbers

Hydraulic snubbers are special elements designed to absorb large impacts in the piping due to seismic phenomena or other circumstances like water hammers.

During the normal operation and movement of piping, they do not restrict movements, offering minimal resistance. However, when a sudden impact occurs, they lock themselves becoming highly rigid supports, protecting the system against that event.

They can be installed in any position with relation to the pipe by the use of special beam attachments (“rear brackets”), highly rigid clamps and special enlargement pipes.

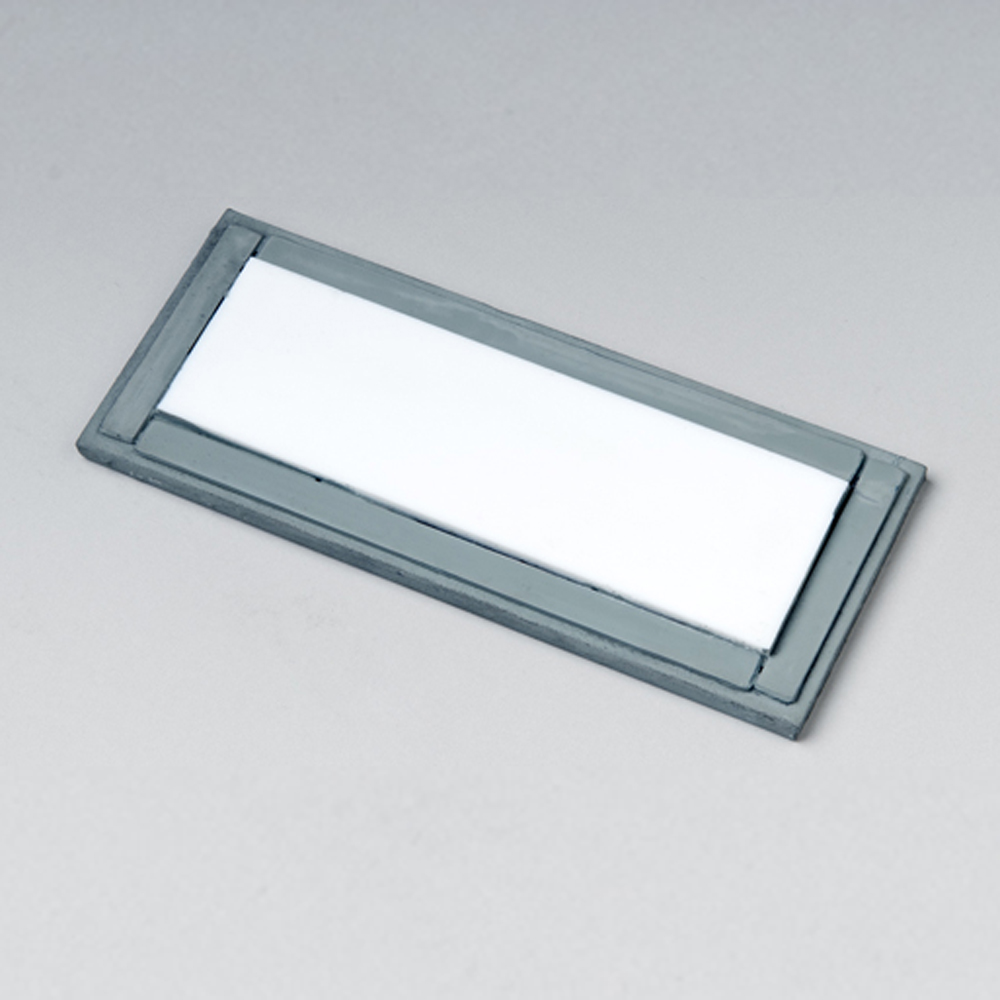

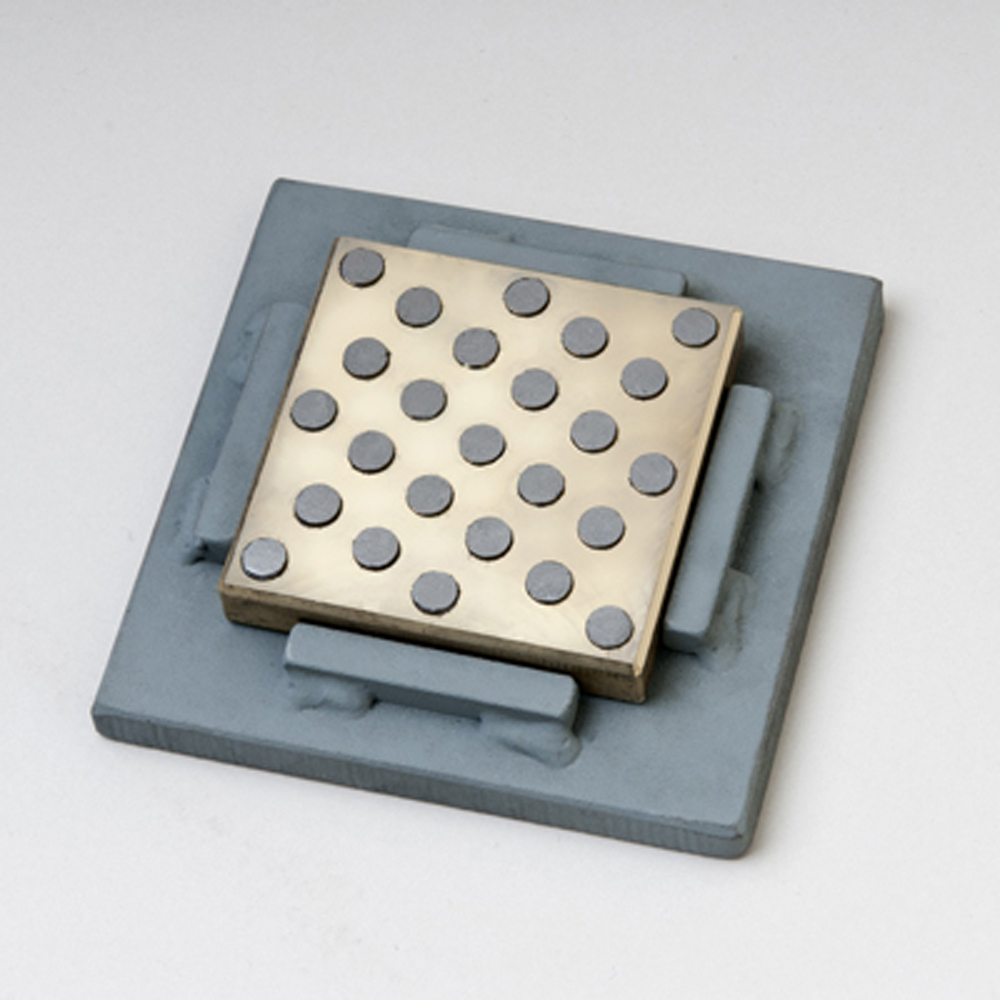

Sliding plates for pipe and equipment supports

Sliding plates are special items that are designed to significantly reduce the friction coefficient in pipe supports. As a result, they lower the values of load caused by the horizontal displacement of pipes or equipment, reducing stress and improving the functionality of the associated resting supports.

They are usually installed between the pipe or equipment and the structure or floor.

The main sliding plate is based on the use of PTFE for temperatures below 150ºC or bronze-graphite for temperatures over that range or when loads or ambient conditions are more severe, or because of its higher longevity.

The PTFE or bronze-graphite component is permanently fixed to a carbon steel base that is designed to be welded to the supporting structure or embedded plate.

As a top slider, it is recommended to use a polished or semi-polished stainless steel plate, in order to ensure a low friction coefficient and a long life span of the main sliding element.

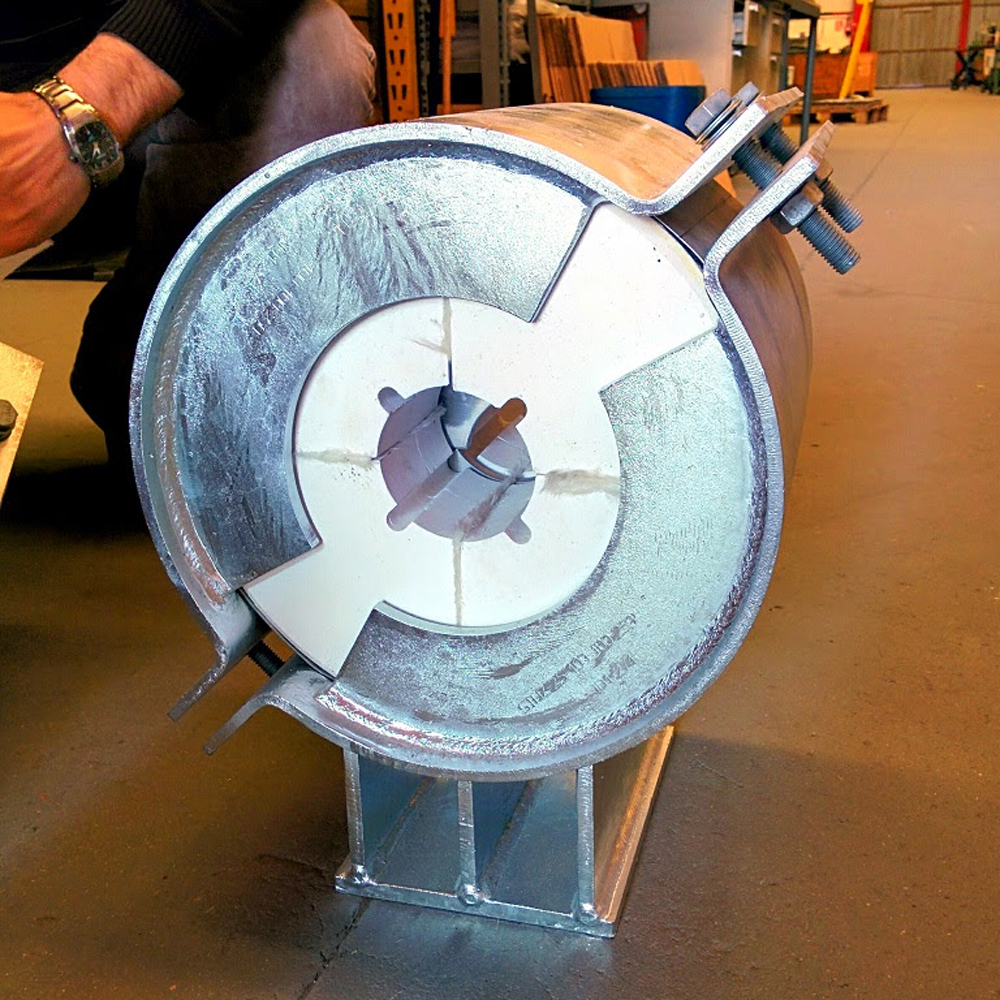

Thermal supports for high temperature service

Thermal supports consist of a steel cradle or shoe with an insulation element between the pipe and the steel support. This insulation component is typically of inorganic material and minimizes the heat transmission from the pipe towards the steel. As a result, in combination with the conventional pipe insulation, it avoids heat loss and prevents the negative impact of high heat in the steel support and associated structure or concrete bases.

There is a wide range of designs for any given pipe size and insulation thickness combination, as well as different installation types in order to obtain a variety of functions (simple resting, guide types, axial stops, trunnion anchors, double shoes, etc.). There is also a number of material types and densities depending on the load to be supported and the degree of thermal efficiency that is required.

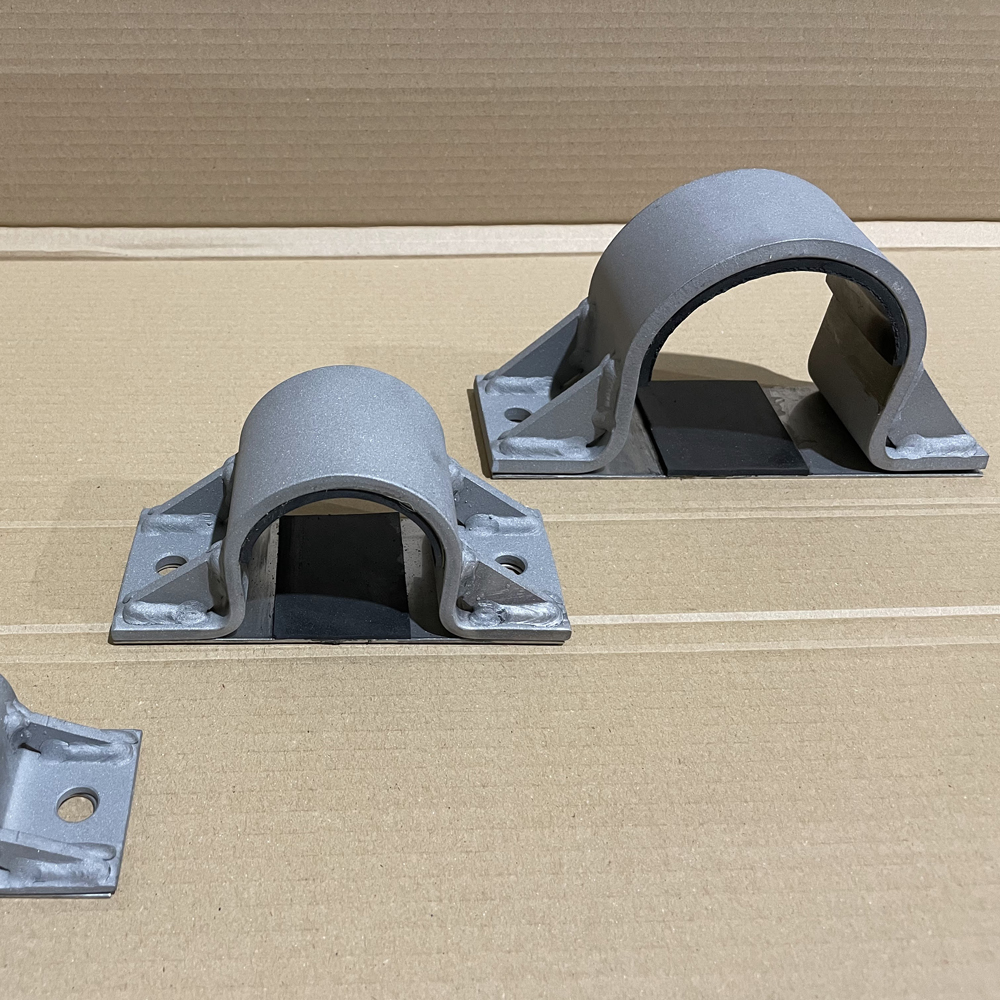

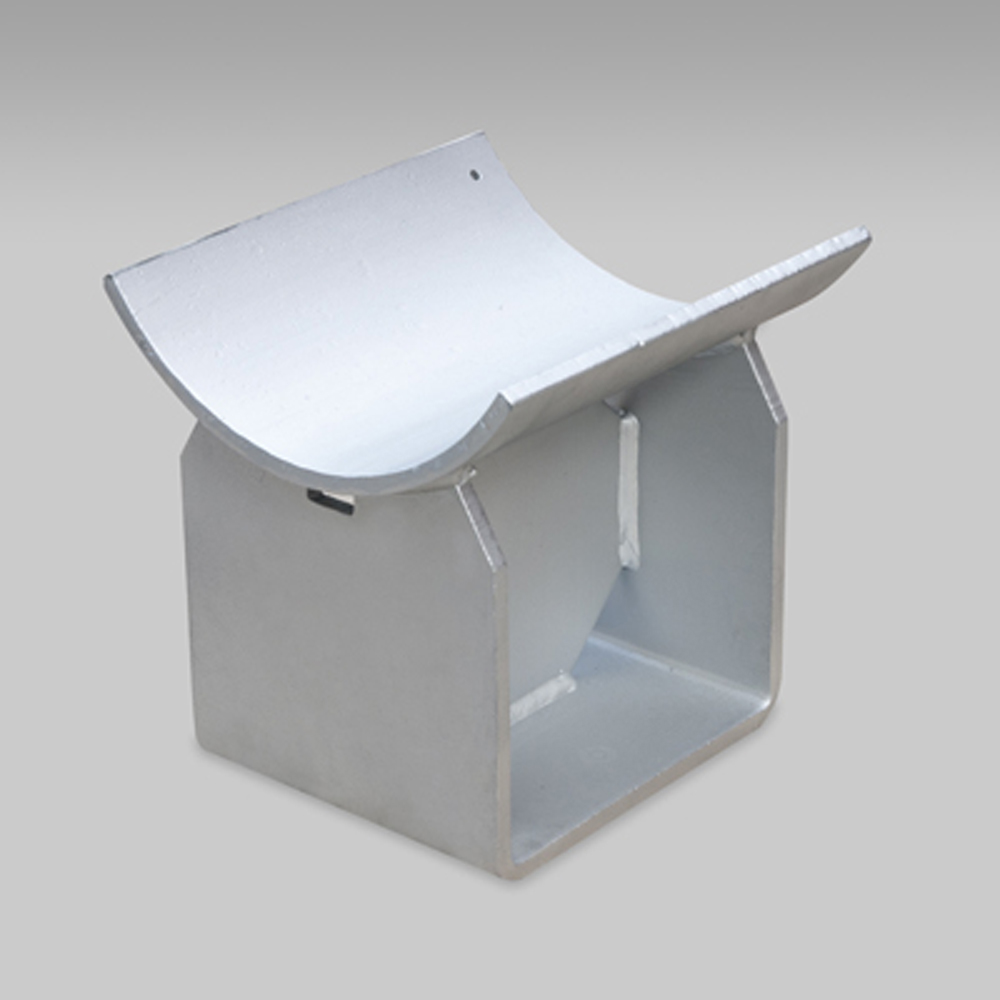

Insulated supports for cold or cryogenic service

We offer a variety of supports for cold service (temperatures around or slightly below 0ºC) and cryogenic service (up to -196ºC), which consist of a combination of steel supports (typically cradles and shoes) with insulation materials of different types:

High density moulded polyurethane foam (PUF)

Densified hardwood

High density resin composites

We will be able to adapt to your project requirements given the endless number of combinations of pipe sizes, insulation thicknesses, support heights, lengths, types…

Special and custom fabricated supports

Although our technical catalogue of standard components covers most of our clients’ needs, our means of production are so flexible that we can easily adapt to third party standards and to adjustments of our standard components.

We are also capable of designing and manufacturing special supports that meet special requirements.

As a result, we can guarantee the maximum satisfaction of our clients’ specifications along with competitive prices and short delivery times.